Ceramic and metallic converters can be highly effective at reducing emissions from automobile exhaust gases, but the specific efficiency of each type will depend on a variety of factors. It’s important to choose the right type of converter for your specific vehicle and to ensure that it is properly maintained to ensure optimal performance.

The catalytic converter is a steel box-shaped element that connects to the car’s exhaust pipe and reduces harmful gas emissions. The catalytic converter renders harmful unburned Hydrocarbons (HC), Carbon Monoxide (CO), Nitrous Oxides (NOx) in the exhaust gas harmless by chemical reaction. Catalytic convertors are used in both diesel and gasoline engines.

The platinum group metals in catalytic converters perform the conversion process. Platinum, Palladium and Rhodium. A typical catalytic converter is mainly made of a porous metallic or ceramic carrier coated with PGM metals.

The catalytic carrier is surrounded by fibrous material and enclosed in a shell made of stainless-steel plate. The PGM layer is put on a ceramic carrier (Al2O3 with e.g., CeO2 -wash coat), which is honeycomb, meaning a dense network of square holes. This type of structure increases the active surface, which is the contact area of the exhaust gases flowing through the channels and the catalytic substances (Pt, Pd, Rh).

Ceramic converters are typically made from a ceramic substrate coated with a thin layer of noble metals such as platinum, palladium, or rhodium. These metals act as catalysts to facilitate the conversion of harmful gases into less harmful ones. Ceramic converters are known for their high efficiency and durability, as well as their ability to operate at high temperatures.

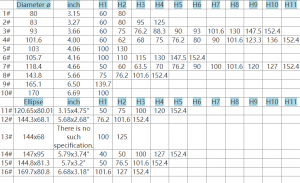

The table below shows the ceramic converters regular size

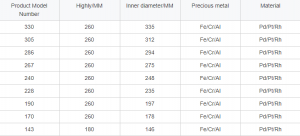

Metallic converters, on the other hand, are typically made from a metallic substrate coated with a layer of noble metals. While metallic converters are generally less efficient than ceramic converters, they are often less expensive and can be more effective at reducing NOx emissions.

Ceramic or metallic carriers are the most important factor in catalytic, which are widely used not only in automobiles but also in all industries. The table below shows the advantages of ceramic and metallic carriers.

| Ceramic Carriers | Metallic Carriers |

| Very High Specific Surface, | Ease Of Heat Transfer, |

| High Corrosion Resistance, | Small Hydraulic Resistances, |

| High Adhesion Of Active Substances, | High Mechanical Strength, |

| High Melting Temperature, | All Visible Dust Density, |

| Ease Of Styling. | Smaller Susceptibility To Mechanical Damage. |

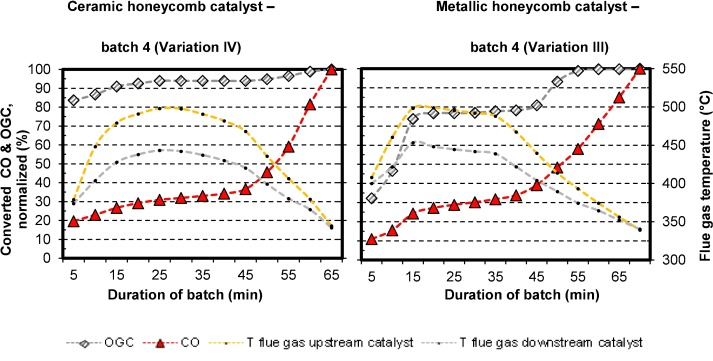

The table below shows the efficiency of the gases converted in the

ceramic and metallic converter.

| Conversion Efficiency | Ceramic Carrier | Metallic Carrier |

| HC | 31,58% | 45,62% |

| CO | 32,08% | 33,52% |

| NO | 43,33% | 47,32% |

CAT Source of getting material from some best raw material manufacturer from Wang Zi Huakai which are best and largest raw material manufacturer in China. Short delivery time If a container takes about 15 days. We also have some standard sizes in stock. If you need a small amount of samples, we can deliver them quickly. We are using the latest Marking Machines for the Logo of our customers.

What we can do for you:

1) We can export you our best superior quality automobile exhaust emissions and industrial waste gas treatment solutions. The company’s products include Honeycomb ceramic substrate, honeycomb metal substrate, TWC, ( universal +direct -fit molds) . DOC SCR VOC DPF Flexible pipe as per your requirements.

2) We offer you our best customer after sale services like repair or replacement.

3) We can also manufacture as per your samples, design and sketches.

4)Please give us your complete postal address we want to send you some samples for checking our quality

5(We can send you our best offer price list for your elevations.

Post time: May-15-2023